WHAT IS COKE

Coke and How it’s Made

Coke is a fuel used in the steelmaking process that is created by heating coal in the absence of air.

Myth: The process of coke manufacturing is very complex and cannot be understood by anyone other than a scientist or engineer.

Reality: The manufacturing of coke involves a number of different processes. An understanding of these processes helps to understand the nature of the air pollution problem. These processes can be broken down and explained in simple terms.

The manufacturing of coke has many associated environmental and air pollution concerns. Coke manufacturing is present throughout the Allegheny County area and impacts communities throughout the county. However, it can be difficult to find specific information about how the coke process and its impacts works.

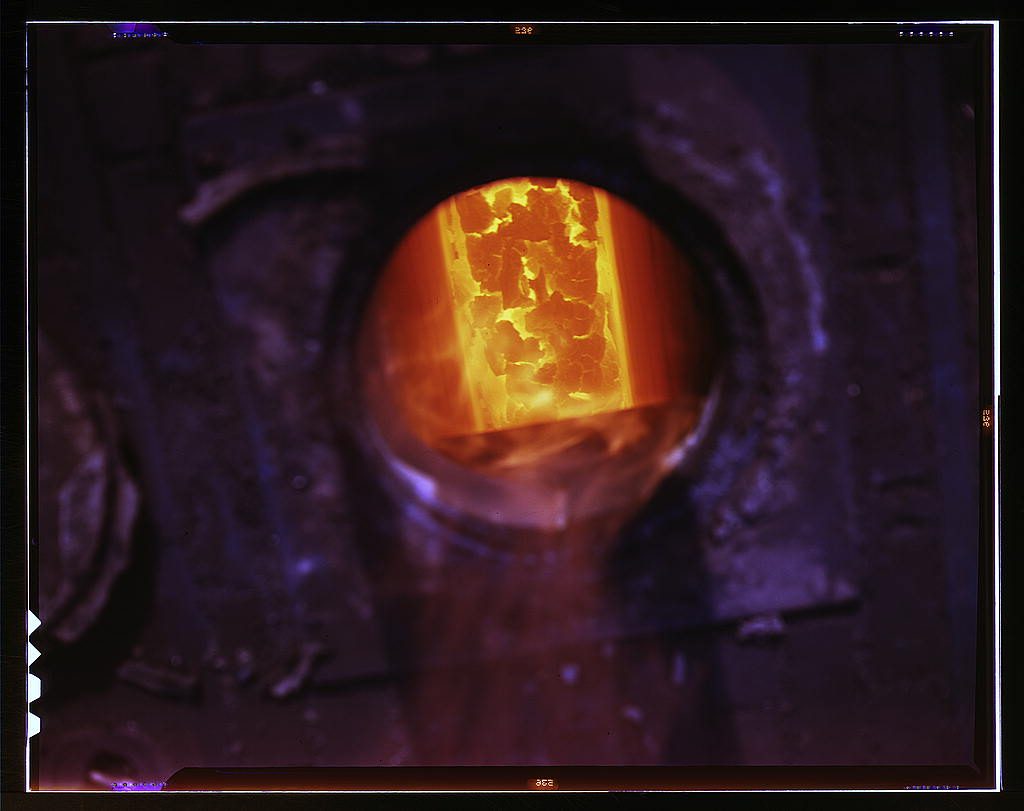

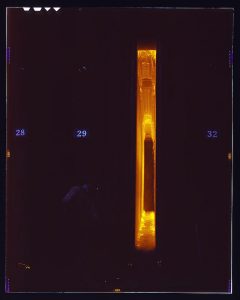

Coke is produced by heating coal at high temperatures, for long periods of time. This heating is called “thermal distillation” or “pyrolysis.” In order to produce coke that will be used in blast furnaces, coal is usually thermally distilled for 15 to 18 hours, but the process can take up to 36 hours. The temperature of the ovens ranges between 900 and 1100 degrees Celsius (1,650 and 2,000 degrees Fahrenheit).

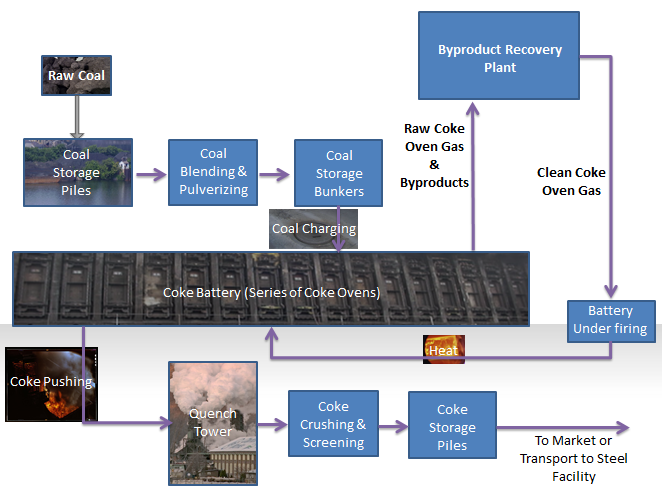

The first step in coke production is the delivery of coal to coke oven facilities, which is usually done by barge or railway. The second step in coke production is to process the raw material, coal, into a consistency appropriate for coke oven batteries.To achieve this consistency, coal is pulverized in a crusher and, if necessary, mixed with water and oil to control the density of the pulverized coal mixture.

A basic diagram of the most common coke making process.

This pulverized coal mixture is introduced into coke ovens, or “charged,” by a “larry car.” The larry car is akin to a railcar that moves across a track that runs along the top of a coke oven battery. Each individual oven has a “charging port,” a door with a lid, that is removed when the larry car is positioned above the oven in order for the pulverized coal to be charged.

After the larry car has charged the coal into the coke oven, a leveler arm is activated to smooth the pile of coal that is now inside the coke oven. In order to allow the leveler to access the coke oven, a “chuck door” must be opened. This leveling process helps ensures that the coke oven gas (COG) produced by heating process will flow smoothly through the coke oven battery’s offtake system.

Once the leveling is complete, the charging port for each oven is sealed by a process called “luting.” The luting process involves pouring a wet clay mixture around the edges of each charging port. This clay helps prevent leaks (fugitive emissions) from the charging port lids during the thermal distillation coking process.

Thermal distillation must be complete before the coke must be removed from the oven, by a process called “pushing.” If coke is pushed from ovens before thermal distillation is complete, it is called a “green push” that produces “green coke”, which results in higher benzene and HAP emissions. The pushing process involves a machine that uses a “ram” to guide the coke out of the oven. The ram guides the coke into a railroad car that is called the “quench car.”

This quench car transports the coke to the nearby quench tower, where the coke is showered with water to prevent the coke from igniting as it is exposed to open air. The quenched coke is then transported to a crushing and screening system. This system processes the coke into the proper size, so it can be used in blast furnace operations at steel mills.